You might have listened to the term flux in welding, but millions of you don’t know the depth of it. The field of welding has such a vast niche that even a single word demands a lot of explanation to understand the concept thoroughly.

Weld metal has one of the most common issues that should be indicated, and this is also mandatory for you to get some good solution for it. We are going to introduce a big problem that is basically related to oxidation and the contamination of the weld metal. But the question is still popping in your mind how to prevent the weld area from this ruthless and stubborn corrosion and oxidation, right?

Flux is the best way to protect the weld area from such issues; although it can’t do anything separately, a little addition to the arc stability will smoothen the path.

So this instructable will teach you what is flux in welding and the other main associated things with flux. So stay tuned and read this informative article till the last line. Go ahead!

What is Meant by Flux?

Flux is a single complex material that is made of both inorganic and organic ingredients. Different materials have their particular applications. Such as the composition of wood flour, cellulose and limestone protect the weld from atmospheric gases while the mixture of lime and silica acts as a flux agent. Similarly, iron powder and titanium dioxide are used to create slag.

These mixtures are used in arc welding and various welding techniques and create strong welds without the assistance of shielding gases.

These fluxes are available in all forms, such as powder, liquid and solid, and can be used before welding or during the process.

What is the Mechanism of Flux in Welding?

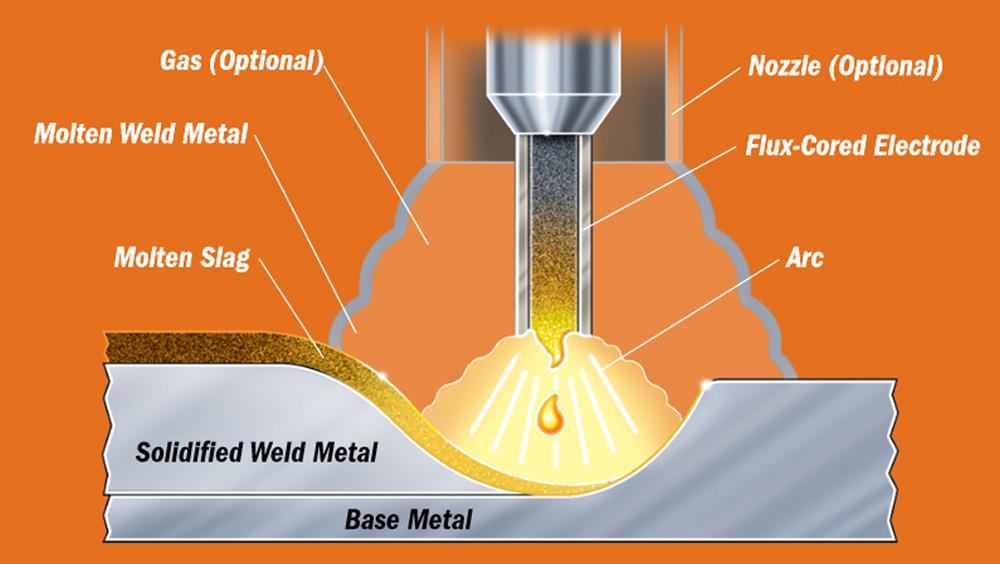

This is already explained that flux protects the weld area from the reactive gases in the atmosphere, but the question arises here how this process occurs?

- Thanks to the simple technique, the flux melts into the weld pool to produce the slag by rising at the top of the weld area.

- This slag reacts with the heat that releases during the welding process, and then the shielding gas is produced.

- This slag and the shielding gas together work to act as a protective barrier against the natural reactive gases to prevent the surface from corrosion and oxides.

- Make sure to clean the weld area from the slag after completing the procedure. The cleaning should be done with the help of grinding or using a wire brush or chipping hammer.

- The welding in which flux is used is also known as slag welding.

What are the Main Types of Flux?

As the flux is multi-purpose same is the case with its types. Different welding’s require different types of fluxes. Moreover, the metal you are going to use in the weld also decides the choice of flux.

There are three basic types of flux, including:

- Low hydrogen flux

- Basic flux

- Rutile flux

Some other fluxes include metal flux, mineral flux, and chemical flux.

A specific type of flux can only be used in a particular type of weld, such as the flux for steel welding can’t be used to treat Aluminum.

What is the Purpose of Flux in Welding?

Now, you have got the complete know-how about the types and the meaning of flux. But still, there is something to tell you about the flux, and that is the purpose of flux in welding.

Here are some significant purposes of flux that are mandatory to be mentioned. Have a look at them!

1. Improves the Appearance of Weld

Welding is a tricky job and demands perfection. If you are a hobbyist, then you can compromise with appearance, but for a professional project, a good appearance is necessary; otherwise, your work would be unacceptable.

So the flux helps in improving the overall appearance of the weld area by filling all the imperfections in the weld.

2. Cleans the Welding Area

Although, while welding, it is the necessary step to pre-clean the area to be welded but it is not a guarantee that the whole area will be contamination free.

As it is already mentioned, with the passage of time, the metal accumulates with oxides; even the joints become impure, so these impurities should be cleaned. This is done by using flux, and you can experience this magic well.

3. Acts as Protective Barrier

Flux is a protective barrier against oxides. The flux not only reduces the spatter but also keeps the weld pool away from corrosion.

4. Increases the Flow of the Filler Rod

The weld material becomes porous sometimes, especially if there is a flaw in the welding process. So you have to locate the issue. If you don’t find any issue, then using the flux will help you to treat the problem.

It helps in improving the wetting action of the filler rod and prevents porosity by creating a strong bond.

5. Easily Treats Difficult Metal

Sometimes, the welder is caught in difficulty when they have to cope with a hectic assignment. But remember, if a welder knows the purpose of flux in welding, then he can deal with any type of metal.

For example, the pot metal is highly unstable and the most tricky to handle, but the flux can conveniently create a strong bond in no time.

Can Flux be Used Indoors?

As you know, welding is a process that requires a special workplace. The area should be ventilated and vast so that possible damages can be avoided.

If you are using the flux indoors, then make sure there is enough air passage; otherwise, there is no such issue associated with the use.

Wrap Up

Flux is a mixture of different ingredients that aid in proper welding. These mixtures vary in composition, so the right flux is mandatory to perform a particular welding process accurately. Flux in welding is popular among most welders because of its many benefits.

Now, with the help of flux, you can make contaminate-free weld joints. Do some practice and enjoy welding!