Many people need basic information on submerged arc welding and how it functions and works! You can check out this webpage; here, we have penned the basic details on SAW.

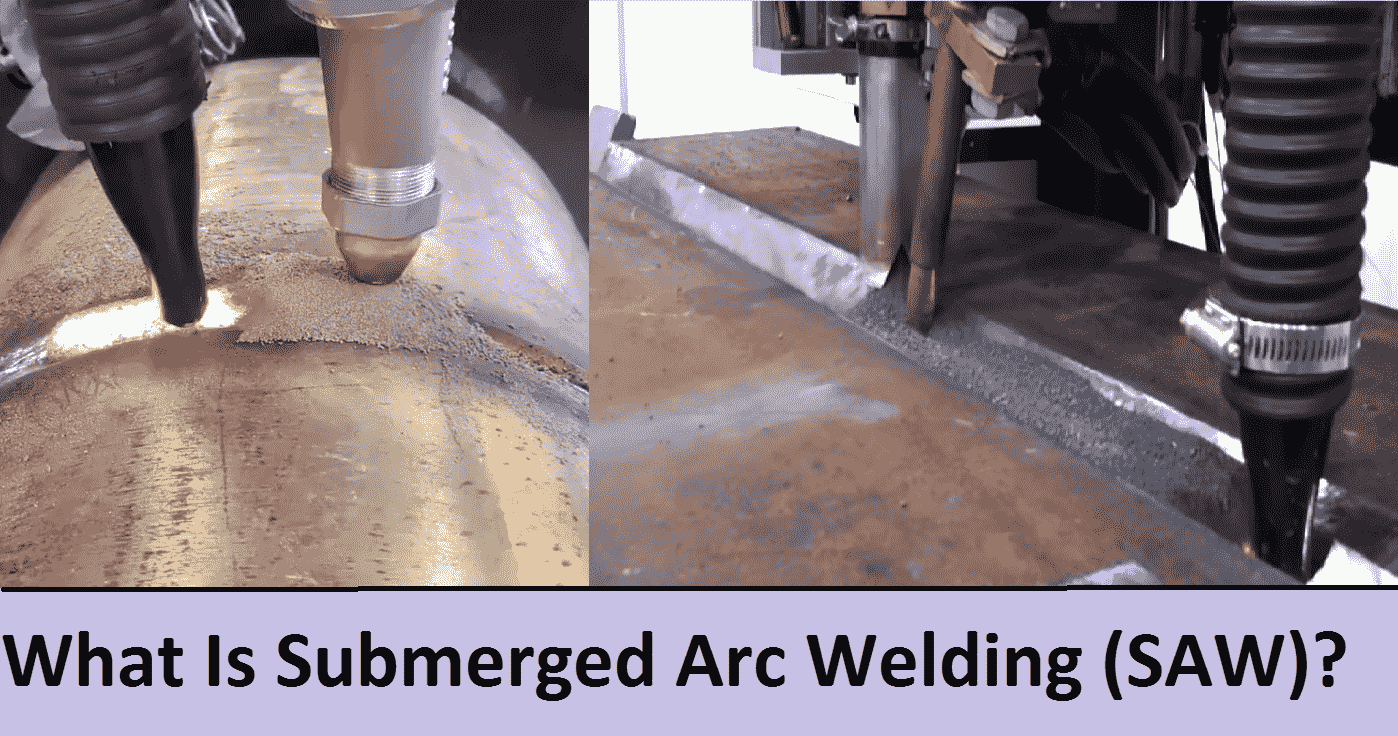

First of all, SAW is abbreviated as submerged-arc welding. It is generally seen that the weld and arc zone are completely submerged underneath a blanket of flux when performing this welding process.

Furthermore, the flux material becomes much more conductive the minute it enters the molten state. This processing creates a path for the current so that it can easily flow between the electrodes and workpieces. The remaining details on the working and primary mechanism of SAW are written below:

- All About The Submerged Arc Welding

- More About SAW

- Applications of Submerged Arc Welding

- What Makes a Good SAW Weld?

- How Does Submerged Arc Welding Work?

- SAW- A Mechanized Process

- Two Welding Consumables of Submerged Arc Welding

- Pros of Submerged Arc Welding

- Restrictions Offered By Submerged Arc Welding

- Conclusion

All About The Submerged Arc Welding

Submerged-arc welding has become the popular and excessively opted welding technique till now. It involves arc formation, and that happens between an electrode and a workpiece. In addition, you will spot a blanket of powdered flux that ultimately generates a protective gas shield and also slag. No doubt, this technique has become the most well-established and versatile method.

To put it in simple words, it is a joining process which primarily involves the development of an electric arc between an electrode and the workpiece that has to be welded. This method is employed in the structural and vessel construction industries.

More About SAW

At times, people call it with the name of Sub Arc or SAW. It only utilizes a granular fusible flux that guards the welded metal against extreme atmospheric contamination. Besides, the flux blanket steadies the arc during welding and prevents sparks and splatter from flying.

Note that it is throughout the SAW process that the flux has to come in the continuously-fed tubular form. When the flux enters into a molten or melted state, you will notice that it becomes conductive and supplies maximum current between the electrodes and the work pieces. Moreover, the entire submerged-arc welding process is automated.

Applications of Submerged Arc Welding

You can apply this welding technique to materials like carbon steels, low alloy steels and, stainless steels, nickel-based alloys. SAW seems a suitable technique to function on surfacing applications, including wear-facing and corrosion-resistant steels.

Its use is getting enormously high in the heavy structural construction sector. You will spot the SAW technique in the pressure vessel industry, chemical plants, and even in the shipbuilding sector.

What Makes a Good SAW Weld?

You will get consistent results if you have performed the SAW technique properly. A good submerged-arc weld shows impact resistance and good bead appearance.

How Does Submerged Arc Welding Work?

The electrode used in the submerged-arc welding process has to be solid. You can even get a cored wire, or the strip can be made of sintered material. On the other hand, the flux can be made by fusing constituents, creating a glassy slag. Or you can make the flux by agglomerating the constituents with the help of a binder and also a corning process.

SAW- A Mechanized Process

Most importantly, the chemical nature of the flux determines arc stability, weld metal mechanical properties and the final shape of the bead. The SAW welding process is basically operated as a mechanized process. In addition, the welding current ranges between 300 and 1000 amperes. The bead shape, chemical composition of the weld metal and penetration depth all depend on the arc voltage and current travel speed.

The submerged-arc welding process remains operated by using a single wire. It is up to you whether you want to AC or DC current. You can gain additional productivity by feeding a non-conducting wire right into the weld pool. This practice will increase deposition rates, improve productivity and enable the SAW process to be commended smoothly.

This technique suits longitudinal and circumferential line pipes and pressure vessel welds. You must carry it out in a flat position to maintain the flux layer and the weld’s pool high fluidity. The arc, which is being “submerged” underneath a blanket of flux, will not be visible as long as you are performing the welding operation. No arc means no fumes will fly away or attack your eyes.

Two Welding Consumables of Submerged Arc Welding

Keep in mind that two welding consumables are part of the SAW process: the electrode and the flux.

- The electrode comes in solid, strip, or cored wire form.

- The flux is made of minerals and compounds. You can produce it in a range of forms and versions.

- You must properly arrange the power source and controls as well as wire feed and flux.

Pros of Submerged Arc Welding

- This process brings high deposition rates and high arc when involved in a fully automated mode.

- It produces minimal welding fume. There will not be a slight production of weld spatter and no development of visible arc.

- It is easy to recover the unused flux.

- You can smoothly make strong, uniform and sound welds.

- This process emits minimal arc light.

- It guarantees deep weld penetration and minimal edge preparation.

- You can easily weld thick materials.

Restrictions Offered By Submerged Arc Welding

- Its use is somewhat limited to steel.

- You cannot carry this technique in a vertical or overhead welding position.

- It needs a separate flux handling system between passes.

- It does not give desired results on thin materials.

- This process looks limited to long, straight seams or pipes.

- You cannot properly apply a flux handling system to it.

Conclusion

Almost every detail on the Submerged Arc Welding has been shared with the readers. It is a popular welding process that offers extensive applicability. Just remember that whenever someone talks about the electric arc formation between an electrode and a work piece, it means that the person is talking about the SAW technique. You can stay connected with us on this platform, and in-depth info on other welding processes will be shared with you.