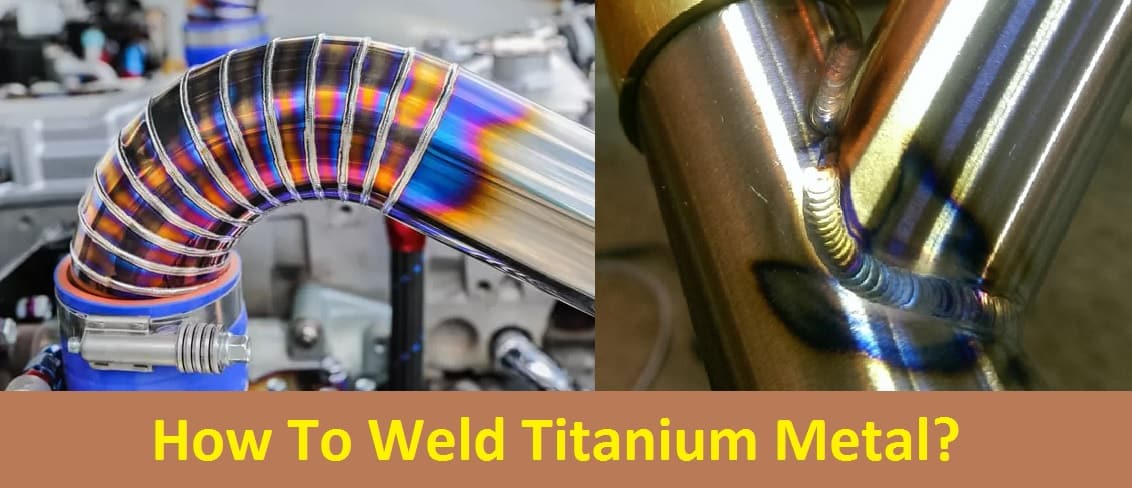

Welding titanium looks no longer a challenging and technical kind of task. You can check out the below-written guide and how titanium is being welded. There are a few important things that you have to keep in mind. Prepare the titanium metal before you start to weld it. Take off the oxide layer and wipe down the whole surface using thinner.

Maintaining ample gas coverage remains a must. In addition, weld this respective metal using a wide diameter cup and back purge the titanium section that is being welded. Here is down below more detail about how to weld titanium metal, please go through the rest of the section of this post:

Basic Information On Titanium Metal

Titanium is very easy to weld. It welds in a way likewise you weld stainless steel. It should be back purged. Furthermore, you must remove the oxide layer before passing titanium through the welding process.

It seems to be a highly reactive metal. It is suggested to weld it in tightly sealed chambers. With proper gas shielding and adopting the right preventative measures, you can weld it perfectly.

A Step-by-Step Guide To Know How To Weld Titanium Metal

You can see the step-by-step guide that tells thoroughly how to weld titanium:

Step 1

The first and foremost step is to set up the welder properly. The welder should have a wire on the spool. Feed the welding gun and check the shielding gas canisters.

Step 2

The next step is to secure the ground clamp to the table on which you will be welding the titanium metal. MIG welders generally have a grounding clamp. A clamp is used to prevent the person from getting electrocuted if he accidentally touches the welding table.

Step 3

Now, hold the welding gun using both of your hands. What you can do is rest one hand of yours on the table and use the other hand to control the gun’s direction. Use the index finger to press the trigger.

Step 4

Position the welding gun tip exactly at a 20-degree angle. This will conveniently allow you to penetrate it into the metal. According to the experts, it is the push position that welders must opt for.

Step 5

You can now turn on the welding machine. Press the trigger which is present on the gun. You will see that a bright spark will be created.

Step 6

Move the gun over the titanium metal slowly and gradually. Keep on pressing the gun tips against the metal. Sparks will be created. It is recommended to leave the gun for at least two seconds on a single spot before you weld the next spot.

Step 7

Make tiny circles with the help of a welding gun as long as you are welding. Just work your way in a downward direction. After some time, hot metal will also pool behind the tip of the welding gun. Once you are done, turn off the welding machine.

Important Things To Keep In Mind

Pre-Titanium Welding Preparation

It is highly important to prepare the titanium metal before welding. Like, removing the oxide layer and wiping the surface with acetone. So, let us talk about the pre-welding preparation:

Clean The Metal Surface, Workstation And Filler

You must clean the titanium metal surface using good-quality thinners or acetone. Remember that the cleaner your metal surface is, the stronger the joint/weld will come out. Using acetone or thinners will remove rust, cutting fluid, oil and dust from the surface and result in a great-looking weld.

Apart from cleaning the metal surface, you should also clean the workspace and filler rods. If you do not follow these three important C’s, there is a high chance that the welded workpiece will become contaminated.

To clean the work surface, you can use a steam cleaner and a dilute solution of sodium hydroxide. This will help you kill away all pollutants and contaminants. Afterwards, use a hot air blower to absorb moisture from the workstation.

Select a Shielding Gas

Now comes the part about selecting a shielding gas! Choosing the right shielding gas is a must because it will decide the quality of the weld. Most welders use 99.999% pure Argon. Only pure Argon and Helium are believed to promise extreme protection and excellent weld quality.

Moreover, buy the shielding gas from reputed and trusted suppliers. The weld quality will become discolored if the argon carries even the slightest trace of impurity. Or you will get a yellowish-tinged weld.

Choose a Filler Metal

Selecting an appropriate filler metal for welding titanium is another important step that you have to carry out. It is recommended to choose the filler metal that is surrounded with the same properties as the base material. Besides, you can choose the filler wire whose strength level is one grade below the base metal.

We can give you some more tips: if you are welding unalloyed titanium and it carries higher strength, it is suggested to use a filler metal that is generally lower in yield strength.

Select The Welding Process

You can weld titanium metal in many ways. Like, you can go for electron beam welding, friction welding, TIG welding, plasma arc or resistance welding,

Conclusion

We hope you have understood the easiest way how to weld titanium Metal. Both pre and post preparation matters a lot. You can share your experiences if you have ever welded titanium or some other metal. Stay tuned!