TIG welding has become an immensely popular arc welding process. For your information, TIG is abbreviated as tungsten inert gas welding. The weld is produced by using a non-consumable tungsten electrode. In addition, the weld area and electrode remain shielded from oxidation and harmful pollutants with the help of inert shielding gas.

To become a pro in TIG welding, you need a lot of preciseness, accuracy, versatility and sophistication. Though the whole process looks increasable and eye-catching to watch, at the same time, it is excessively challenging to perform as well. Here you will know more about TIG welding, so let us see the details without wasting any second:

History of TIG welding

TIG welding is also called Gas Tungsten Arc Welding and is abbreviated as GTAW. This respective process only uses a non-consumable tungsten electrode for producing the desired weld. During the time of 1940s, this technique became a huge success for joining magnesium and aluminum.

Furthermore, the weld pool remains protected using an inert gas shield rather than a slag. If you have already performed manual metal arc welding or gas welding, you might not face any hassle in performing TIG welding. Due to this technique, welders have started accepting aluminum to perform high-end welding and other kinds of structural applications.

All about the TIG welding

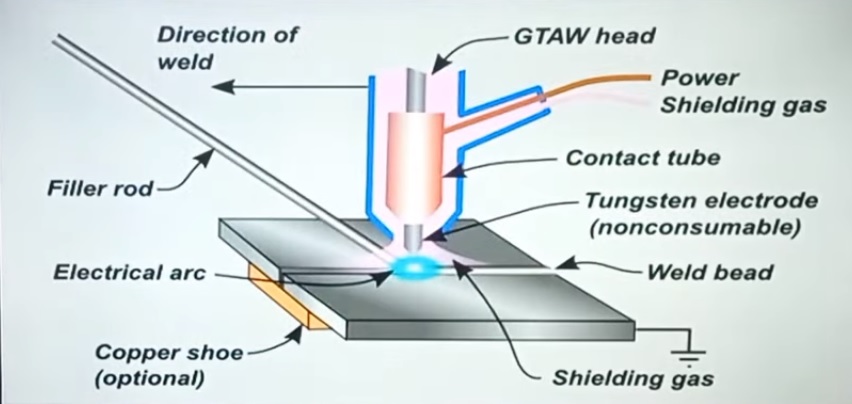

Tungsten electrode is basically used to join metals and create an arc while carrying out TIG welding. You can use the shielding gas, either pure argon or mix the argon with helium so that no contaminants and oxidized layer come on the weld and electrode. This process employs direct current ”DC” and alternating current ”AC”. It depends on the metal type you want to weld or join and which current can be used.

One of the interesting traits of this process is that no physical contact is made between the metal pieces and the electrode. Moreover, no electrode seems to be consumed during the whole welding process. The arc remains completely stable and clean and manages to produce good, uniform and straight welds.

The working Mechanism Of TIG Welding

TIG welding technique works by simply melting the base metal. An electric arc which is generally formed right between the grounded metal and tungsten electrode, is used for melting the base metal. Below you can see more details:

Tungsten Electrode

The tungsten metal gets melted at far higher temperatures during the TIG welding process. It reaches 3422°C. And the tungsten electrode manages to withstand excessively high heat.

The minute the tungsten becomes hotter, you will see that the electron-emitting process will get improved and ultimately produce the most stable and clean arc. Grinding the tungsten electrode lets you shape the arc and also the cone width.

Filler Metal

With or without the filler metal, you can perform the TIG welding process. To get strong and stable joints, it is always recommended to use a filler metal. Adding filler metal seems to be the challenging aspect of tungsten inert gas welding. What you need to do is to dab the filler wire right into the weld pool meanwhile controlling the TIG torch.

Shielding Gas

The primary purpose of inert shielding gas is to fully secure the tungsten electrode and molten metal from contamination or oxidation. Furthermore, you catch up with a clean and stable environment. Popular shield gas options are argon and helium.

Applications of TIG welding

- You can have it for welding and joining exotic metals, and that includes aluminum and stainless steel and also nickel alloy and magnesium.

- Its use is excessively seen to weld mild steel.

- Overall, its use is applicable to almost all industrial sectors. You can apply its operations to mechanized systems.

What Kinds Of Materials Can You TIG Weld?

You can easily weld aluminum or magnesium and catch up with maximum joint quality. This technique lets you perfectly and smoothly tailor the arc, which is utmost needed to weld aluminum or magnesium pieces.

Opting for TIG welding claims to offer a 100% finished look. In this technique, aesthetics plays the most important part. Stick and flux-cored welding do not provide pretty welds and TIG welding achieves and successfully acquires the best results.

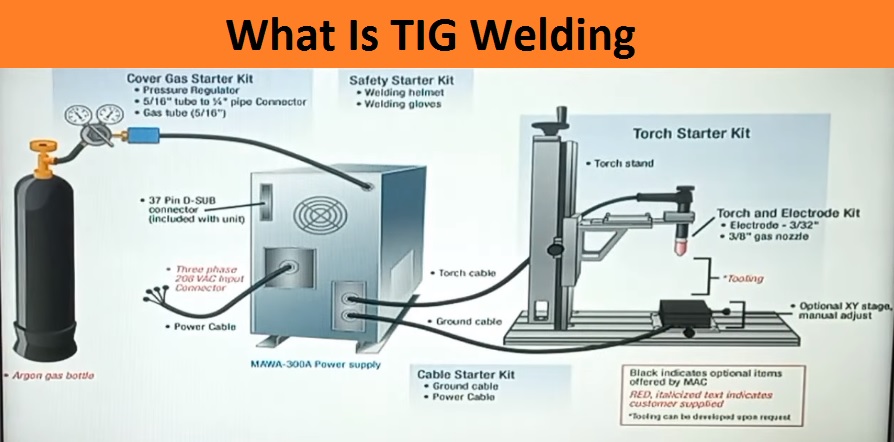

Equipment Needed For TIG Welding

The below-mentioned TIG welding equipment is needed basically:

- You need a TIG welder, and the chosen welding machine should be able to support AC TIG output completely.

- Get hold of the tungsten electrode; you can even have the electrode made of lanthanum, cerium or thorium.

- You need to use ER70S-6 for welding general mild steel. Moreover, have ER308 for welding 200 and 300-series stainless steels.

- Instead of renting out the shielding gas tank, it is recommended to buy and refill it. Argon gas bottles work great for many welding jobs.

- Get a good-quality welding helmet and gloves. These are the important gear that guarantees a welder’s life safety.

- Foot pedal lest you regulate the amperage output.

Career Prospects In TIG Welding

If you have seriously decided to opt the profession as a TIG welder, trust us; uncountable career prospects and multiple working opportunities will come regularly. The popular job options are to serve in the aerospace and pipeline industries. You can work for sectors like fabrication, structural welding and food and beverage industries. In addition, the oil and gas sector demand TIG welders on the highest note. The list of industries is just endless which genuinely hunt for a pro welder every single day.

Career Prospects In TIG Welding

Conclusion

What else do you want to know about TIG welding? Regardless of your query level, you can share it with us, and we will reply to you. TIG welding has made its name and strong presence in almost every sector and industry. Get hands-on training as a TIG welder and earn a handsome amount throughout your life. Stay tuned!