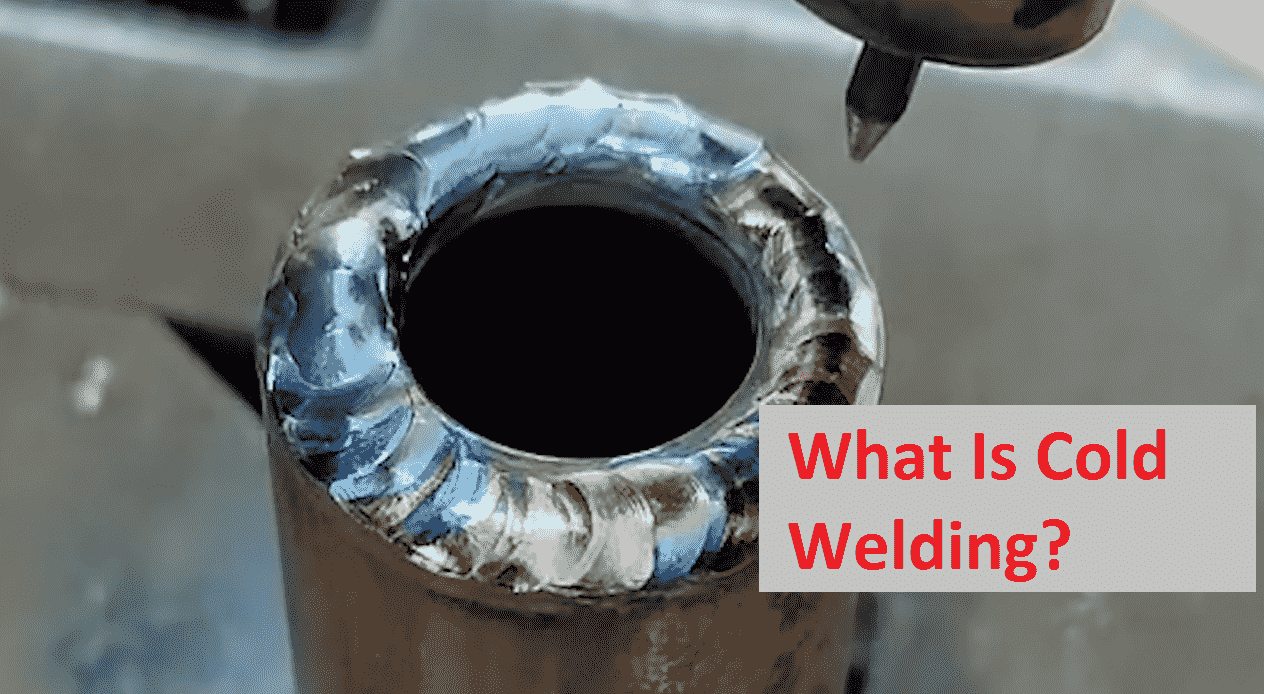

Did you hear the word “Cold Welding” and now looking for its meaning? In this blog, we have a lengthy discussion about what is cold welding, so stay with us to know!

Cold welding is a distinguished phase of welding in which we join or connect two solids at medium temperature without melting or converting them into a molten state. Unlike other welding processes, we apply high pressure instead of elevated temperature to bring them together.

If you have developed an interest to learn more about what is cold welding and all about the characteristics, advantages, and disadvantages of cold welding, glue your eyes to the screen and read below!

How Does The Science of Cold Welding Work?

Let’s discover how the amazing process of cold welding initiates!

The process of cold welding starts when the two solids are brought together at high pressure but ambient temperature. The pressure is destined to close the atoms of metals so that they can be joined.

The most common problem faced during the mechanism of fixing them both with each other is the presence of metal oxides. Metal oxides hinder the fixation of both metals, so first of all, we have to remove the oxide layer.

For this purpose, we’ve to clean the metals and then weld them together. Applying pressure on the cleaned solids so that they can form a strong metallurgical bond can help to achieve highly precise welding.

What Are the Characteristics of Cold Welding?

If you want to find the weld that you are seeing is a cold weld or not, you can judge by knowing about the characteristics of cold welds:

- The metals can be similar or dissimilar

- There will be no sign of heating

- Both metals will be cleaned

- Two metal pieces can be separated by applying a great force at short sections

- The developed form of workpieces will be stronger than the parent metals

- The electrical characteristics will be the same as that of parent metals

What Are the Types of Cold Welding

Are you wondering how a weld can have different types? Let it clarify! Three different methods are used in the cold welding technique, which are given below:

#1. JB weld

JB is branded adhesive that helps to get some type of solids like fibreglass, concrete, and bricks attached. No “so-called” welding is done during the process, but the epoxy component of the product makes them join temporarily.

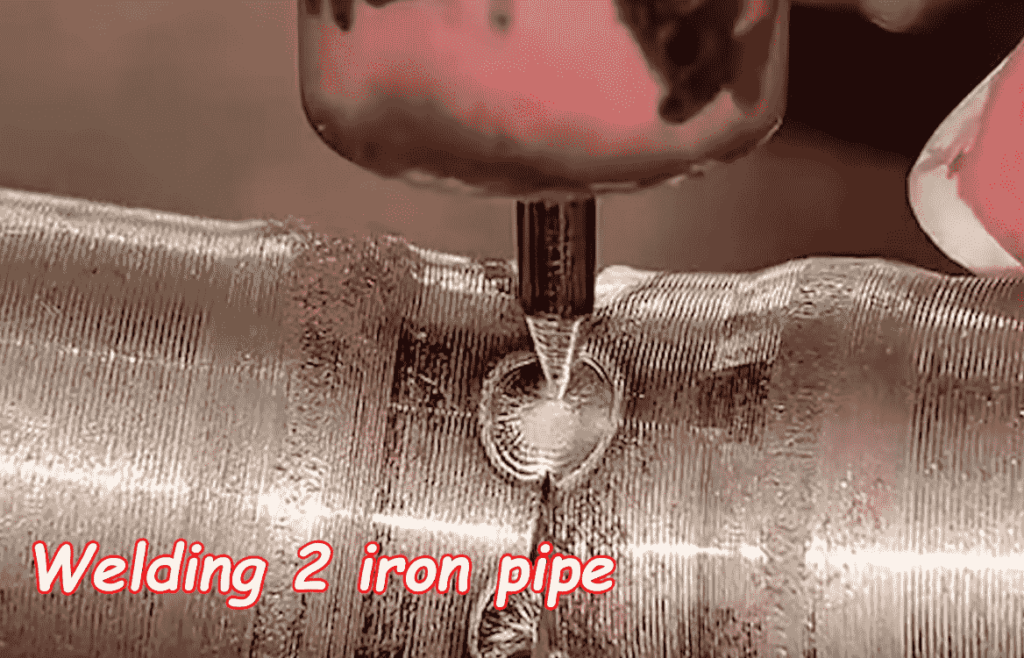

#2. TIG weld

This type of cold welding is significant for joining thin solid sheets. A tiny arc spot is applied for a few seconds. The heat dissipation due to metal conductance is high, which makes the temperature minimal, and it becomes a “cold” welding method.

#3. Cold Metal Transfer

This is often confused with cold welding, but actually, it is a MIG method of welding, but the heat input is 90% reduced as compared to the original MIG welding. This character makes it closer to the science of cold welding.

What Are The Advantages of Cold Welding?

Why today do we prefer cold welding over other types of welding? Certain reasons make it more beneficial for the repairing process. Let’s have a look at them!

#1. Cleanliness of Piecework

The most distinguishing characteristic of the cold weld is that there will be no mess around the joints. You do not have to clean the dirty region around the joining points, as happens in other types of welding.

#2. Absence of HAZ

HAZ or heat-affected zone is not present in the case of cold welds as you have not applied high temperatures that could scar the metals.

#3. Strength of Metallic Bond

Pressure can help to avoid the failure of strong bonds during the welds. The bond of connected metals will be far much strong as compared to the parent metals.

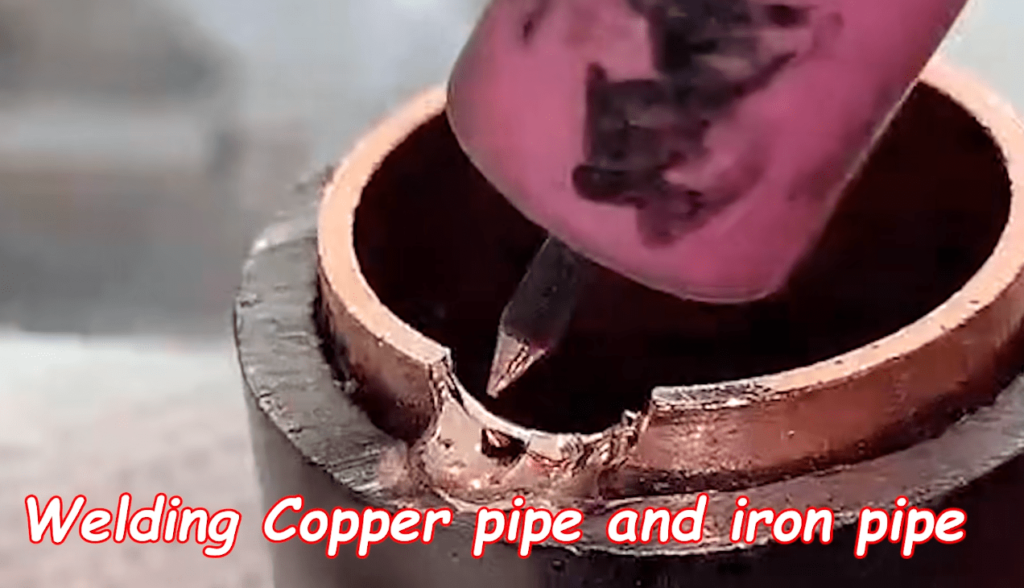

#4. Dissimilar Metals

In other techniques of welding, we cannot weld two different metals because of the difference in their melting points. But cold welding provides a great advantage over two dissimilar metals like Aluminum and copper, copper and silver, and many more.

#5. Simple and Inexpensive

If you know how the process is done, you can understand how simple and inexpensive cold welding is. The two ends are bonded automatically due to the inter-atomic attraction of solid metals.

What Are The Disadvantages of Cold Welding?

Despite all the benefits that cold welding offers, there may be some causes that make it unsuitable for your welding needs. Here are some of them!

#1. Specific Materials

What type of solids can be incorporated through cold welding? This question makes it unreliable for all types of materials. Only soft and ductile metals should be welded by the application of pressure. So the metals with a hard coat cannot be joined in this procedure.

#2. Time-Consuming Process

The technique of cold welding is time taking. You have to remove all the dust, cumbersome, and oxides before going for the cold welding; it means a great amount of time is invested in this process.

#3. Chances of Alloy Formation

Another problem we have to face is the formation of alloys instead of welds. Why does this happen? When we bring the metals close to each other through great pressure, one metal tries to replace or blend with the other.

#4. Irregularities

Are you trying to weld two metals that are different in shape or size? It may not work because the applying metals shouldn’t be irregular but linear to be welded. The strong welds are done only with flat and regular surfaces of metals.

#5. Difficulty in Inspection

When cold welding is done, the thickness of the metals is reduced. The limitation is you can not inspect whether the metals are joined significantly or not because this is done in a solid phase.

Concluding Words

Cold welding is a unique type of bond formation between metals that does not include heat but pressure. Three types of cold welding are common. There are many benefits of cold welding, but there are some reasons which have limited its use.

We hope that now you have a clear concept of what is cold welding and what makes it unique and preferable.

Thank you for sparing your precious time to read this blog!