Are you a hydrophilic or hydrophobic person? For a hydrophilic person, this article would surely be a piece of great interest!

If you are a welder and want to earn more from the job, then listen, ground welding is not your destination. You should do something extraordinary, and that is hyperbaric welding.

Hyperbaric welding is a special kind of welding under the high pressure of water. If you have just joined the welding profession, then this term might sound new to you. In truth, the reality is different!

This particular type of welding has a long history, and with time, it has become more advanced. Although hyperbaric welding creates a very risky environment but authentic knowledge of how to perform hyperbaric welding, a welder can save himself from potential damage.

Just like another welding, this technique has special protocols that you need to know about if you are also a part of this niche. So stay tuned and read with us about what is hyperbaric welding till the last line. Go ahead!

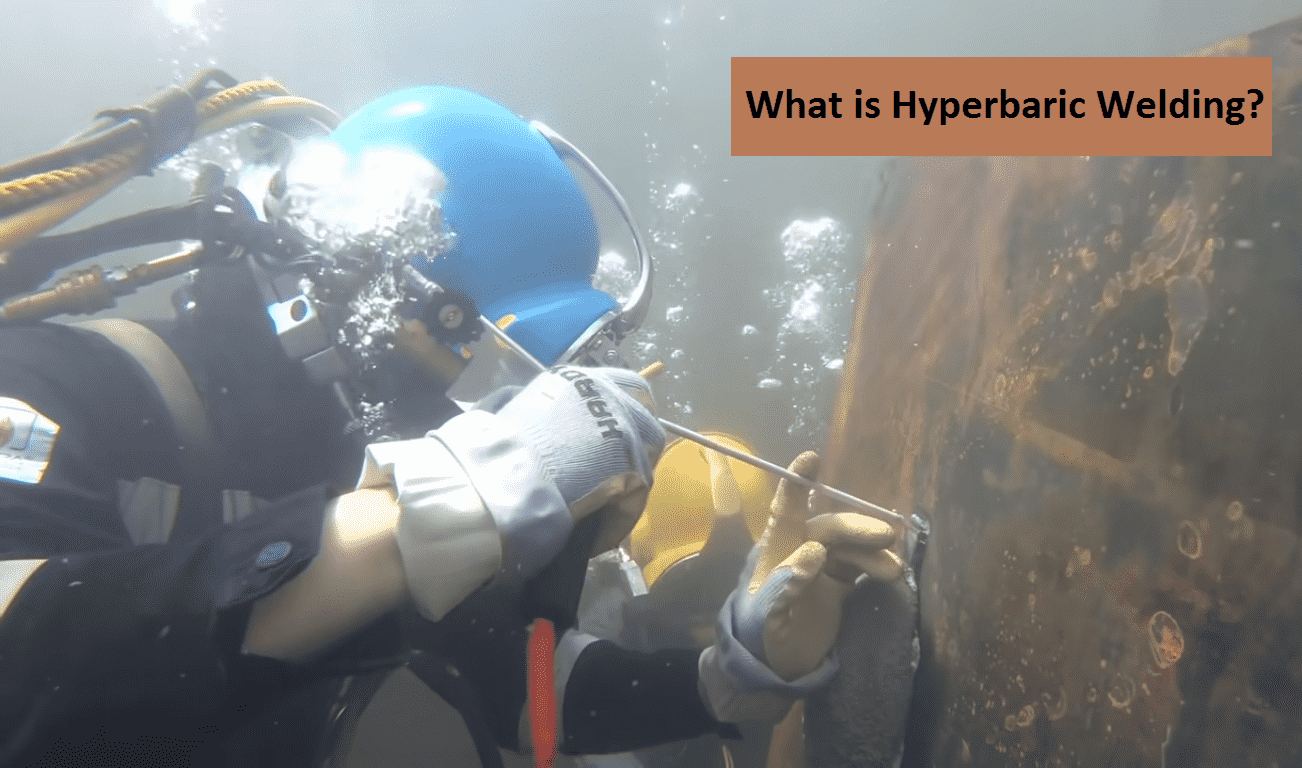

What is Hyperbaric Welding?

Hyperbaric welding or welding underwater is a particular type of welding that is done under high water pressure to repair ships, pipelines, and offshore oil spills. Many of you might be shocked to hear this because the mixing of water and electricity in the same process is perplexing!

But honestly, the process is not as dangerous as you think. A good practice with complete technical knowledge is enough for protection.

Here, a good thing to remember about this type of welding is that it depicts the welding that is performed under water pressure but in a dry environment, and if the welding is performed in a wet environment that it would be predominantly called underwater welding.

Hyperbaric welding is generally done at a depth of 3300 feet for high-quality welds.

What are the Requirements of a Hyperbaric Welding?

Welding is such a process that always demands proper equipment. A single missing tool may cause an interruption in the process that may delay the project. The same is the case with hyperbaric welding. So for a professional welder, it is mandatory to gather this equipment before planning the assignment!

1. Diving Suit

While performing ground welding, we always try to have a suit that is made of 100% cotton fabric to avoid burning. Similarly, hyperbaric welding requires a dry diving suit. For climate control, a dry-diving suit is the best option for a non-hefty welding process. Adding a coverall on the suit acts as an extra shielding layer as they prevent the suit from burning.

2. Diving Accessories

There is an essential list of some underwater diving accessories, and they all are necessary for a diver to gather. These include:

- A multi-purpose diving knife

- Harness to help in floating

- Bailout gas which is a secondary gas supply to handle emergencies

- Umbilical cord as a primary gas supply

- Gas panel and compressor to keep an adequate supply of air

- Knife switch to regulate electricity to power the device

3. A Safety Diving Helmet

Helmets are the most important equipment to proceed with the welding process, whether it is ground welding or hyperbaric welding. One more thing, you can’t compromise on the quality of a helmet; even if it costs much, you should spare some money to invest in it.

A diving helmet prevents both face and eyes from high water pressure and also ensures breathing while diving. The eye shields are mostly customized, so you can flip them up or down when needed.

4. Power Supply

Make sure you have a perfect power source for the welding underwater. A direct current power supply is usually used for hyperbaric welding.

5. Electrode

An electrode with high-yielding strength and water-resistant coating is extremely useful in providing the material for welds in the hyperbaric welding process. Make sure you have one!

6. Stingers

Have you thought about holding the electrodes underwater? Do you have some tricks in mind? Definitely No! But stingers can help you in this regard. These are well-insulated and lightweight, made with plastic that is ergonomically designed to hold the electrode without a twinge.

What is the Chemistry of Hyperbaric Welding?

The process of hyperbaric welding should be clear to you. So we have brought a brief introduction to its mechanism.

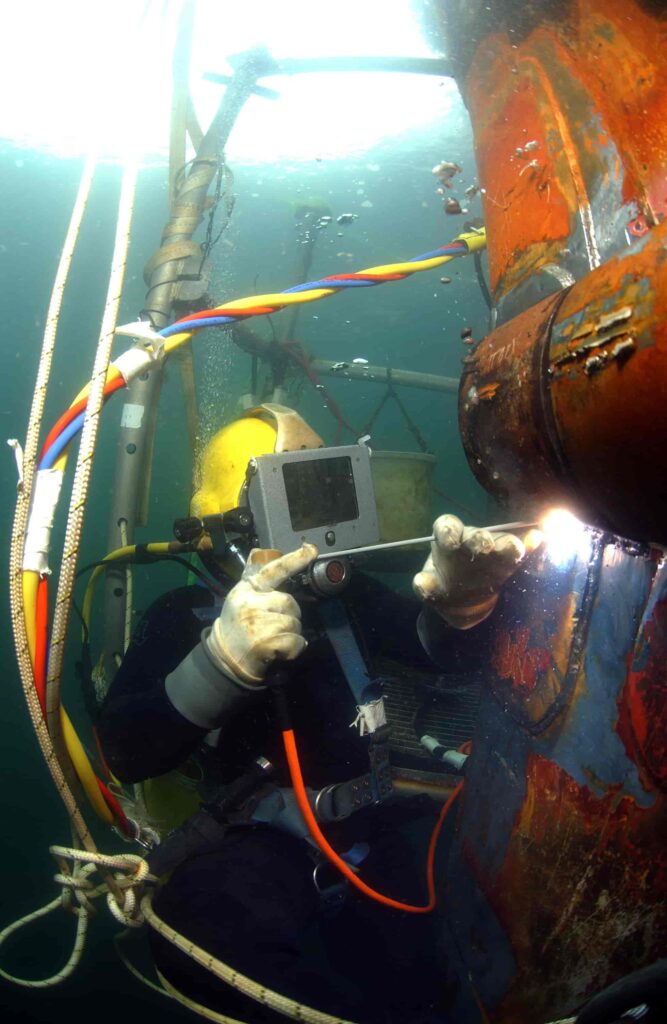

Hyperbaric welding uses a hyperbaric chamber where most of the welding occurs. This chamber is sealed around the weld structure. After sealing, the connected hoses flush the water out and then replace it with a mixture of gases. The preferred mixture of gases is oxygen and helium.

After this, the hyperbaric chamber plays its role in avoiding decompression sickness; it happens when the chamber is pressurized to the correct depth.

What are the Types of Hyperbaric Welding?

This underwater welding technique has further four types that welders can use. These include:

- Pressure welding – which is used for working in a pressure vessel.

- Dry spot welding – which is useful to perform welding in small hyperbaric chambers.

- Dry chamber welding – that allows a welder to do his job without being fully covered underwater.

- Habitat welding – allows welding in a small chamber that has the same water pressure as outside.

What are the Benefits of Hyperbaric Welding?

Hyperbaric welding is a useful welding with so many attractive benefits. Although risk factors are associated with this welding, the handsome salary package encourages welders to excel in this field with skilled knowledge.

So here we have compiled the advantages for you!

. Hyperbaric welding guarantees the divers’ safety, especially if the diver has appropriate suiting and all the vital equipment as mentioned above.. This is a non-destructive type of underwater welding.

. The weld produced as the result of this process has high quality.

. Hyperbaric welding has surface monitoring; that’s why it is an incredible blend of engineering excitement.

Wrapping Up

Working with metal under the sea is such an interesting job, but not for the people who have fear in their hearts. A diver should have a big heart to tackle the nerves, and he must have the right information on how to deal with the welding. Get perfection before commencing!