They say welding is more than just grabbing a stick and going to work. There is a lot of knowledge and science involved in the whole process.

For instance, in Tungsten Inert Gas Welding, 100 percent pure argon is used as a shielding gas, whereas, in Metal Inert Gas Welding, a mixture of 75 percent argon and 25 percent carbon dioxide is used to safeguard the welds from atmospheric contaminants. This doesn’t happen by chance or by choice. There is science and knowledge behind it.

Let’s see how science is involved in this case! Tungsten and carbon dioxide are highly reactive substances. There is a high chance of them reacting together and forming tungsten oxide. Tungsten oxide has a high tendency to contaminate the weld. This is why welders don’t use a mixture of argon and carbon dioxide in the case of TIG welding.

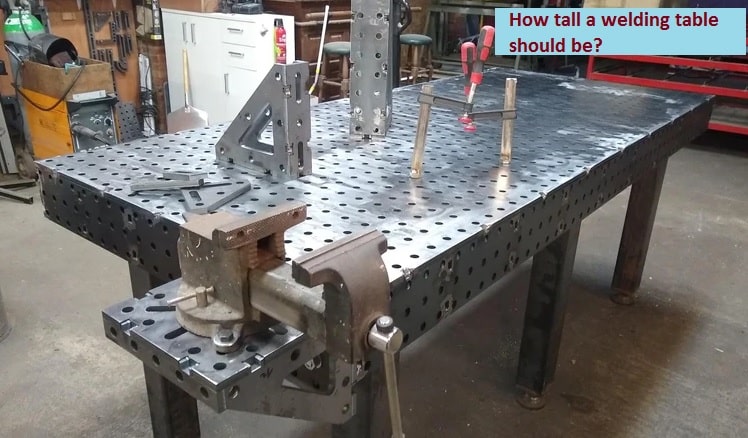

Likewise, it is imperative to ponder upon some worth-noticing points when choosing this profession. That said, to help you out, this writing has thrown light upon one of the main concerns of young welders, and that is, ‘How tall a welding table should be?’.

Let’s just dive into the ocean of information waiting to welcome you with open arms!

Why is the Height of The Welding Table Worth-Considering?

Choosing the correct table height is as important as drinking water. This is because incorrect table height would result in an unfortunate and distressing experience for young and old welders alike.

Let’s see what happens when you choose the improper table height!

1. What Happens If The Welding Table is Too High?

In your primary school, you must have encountered or observed an uncomfortable experience of a student who has to deliver a speech in the morning assembly, but his height is too short of matching the height of the rostrum.

Likewise, you would have observed that you didn’t perform well in exams during which your chair or desk was uncomfortable. You had a hard time writing down on your answer sheet when the height of the table or chair was too high compared to your height.

From that, you can interpret the importance of a table that is not too high. When a table is high, welders often feel acute pain in the shoulder, neck, or upper arm. No man can give his 100 percent at work when the table is above the worker’s head.

2. What Happens If The Welding Table is Too Short?

Welders who have previous experience working with welding tables that are too short in comparison to their height have largely suffered from chronic pain in the lower abdomen.

These welders have complained that leaning forward for continuous hours puts a strain on the lower back and causes chronic pain that lasts for weeks or months. This is because, during welding, a welder is not only providing support to his body but to protective gear.

Welders also need to take good care of welding accessories like clamps, torches, materials, and fixtures. This is why it is important to choose a welding table that has the best height – a height well suited to the welding process and matches the physical height of the welder.

How Tall Should a Welding Table Be to Ensure Maximum Productivity?

Just like humans get affected by environmental factors, the same happens with the welding tables too. The height of a welding table depends upon factors like the welder’s height, the type of welds that the welder expects to obtain by the end of the process, and the frequency of table usage in the process.

Before moving ahead, take a moment and ponder over a simpler fact that says the more lengthy the project is, the more you feel comfortable on the floor. However, if the project you are working on is not lengthy but demands high precision and accuracy, then a welding table is the best choice for you.

Have a look at the numerical figures penned down next to get an idea of the height of the welding table, together with the estimated height of a welder.

- If the welder’s height is between 5’3″ to 5’7″, he should go for a welding table that stands 36″ from the Earth’s surface.

- If the welder’s height is between 5’7″ – 5’11”, then he should pick up a welding table whose height would be around 38″ from the ground level.

- If the average height of a welder is between 6′ – 6’2″ then he should invest in a welding table that would be 39″ – 40″ above the ground.

- If the average height of a welder is 6’2″ or above, then a welding table that is 41″ above the ground level is the best option for him.

One of the most efficient ways of checking which welding table suits you is to experiment with the old table. Spend time with old tables of various sizes to see which one suits your needs. After you are sure about the size, go on and order one for yourself.

Things That Are Worth Noting When Buying a Welding Table

It is a general rule of thumb to take certain things into account before making a purchase. This will greatly ameliorate the likelihood of money wastage.

While buying a welding table, you need to take into account the following points;

1. Welder’s Physical Height

A welding table that is equal in height to the height of the welder’s waist not only assures enhanced productivity but also provides a painless and comfortable work experience for the welders.

2. Size of a Project

The larger the project, the larger table you would need so that you could focus on everything and anything.

3. Your Position While Working

Welders who stand for a maximum time while working would feel more comfortable with the table equal to the height of their waistline. However, if welders rarely stand while working, then they should not invest in welding tables.

Final Statement

A welding table which is equal in height to the height of your waistline provides a comfortable work experience for the welders. For details about the height of the table and its importance, follow the article from the start!