Welding is a critical skill in many industries, from construction and manufacturing to automotive repair and metal fabrication. But not all welding machines are created equal. Some are designed for heavy industrial use, while others are better suited for lighter, hobbyist projects. Additionally, the materials being welded, the thickness of the metal, and the type of welding performed will all play a role in determining the best machine for the job.

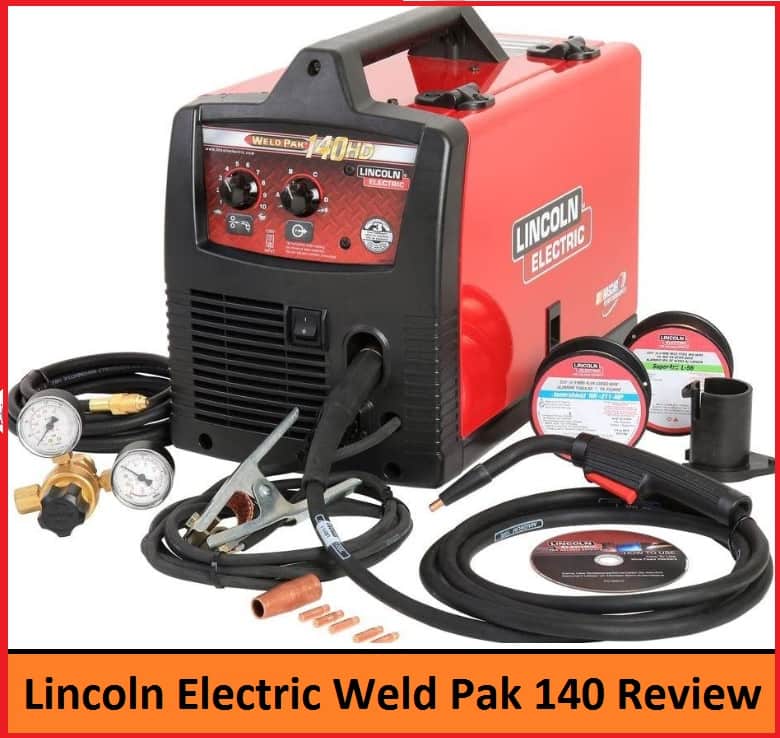

The Lincoln Electric Weld Pak 140 is a great choice for those looking for a machine that can handle various welding tasks. It is capable of MIG welding, the most common type of welding used in light industrial and hobbyist projects. Additionally, this machine has a wide range of amperage settings, which allows for different welding types of metal thicknesses, and has a built-in wire feeder that makes it easy to use.

It also includes a dual-groove quick-change drive roll that allows for easy changeover between the solid and flux-cored wire and a built-in gas solenoid valve that eliminates the need for a separate gas connection. It also has thermal overload protection, preventing overheating and damaging the machine. It has many other features to appreciate that you will find out in this Lincoln Electric Weld Pak 140 review!

Overview of Lincoln Electric Weld Pak 140

Lincoln Electric Weld Pak 140

- Powerful Performance

- Wire-Feed Mechanism

- Portable Design

- Adjustable Settings

- Quality Construction

This is a great choice starting with lincoln electric 140 pro MIG welding. Also, if you’re a professional welder needing a reliable MIG welder, it is portable enough to bring along on projects when a more powerful welder isn’t required. The output levels may be adjusted from A to D by a rotary dial included with the device. And that adjusts the welding current from 30 Amp to 140 Amp.

You may regulate the rate at which the welding wire is expelled by turning the other dial on the front of the machine. Your Lincoln 140 HD welder will be unable to weld due to built-in safety features. The front indicator light will switch on as well. Mild steel thicknesses from 24 gauge to 3/16 inch may be welded with a single pass using a Lincoln Electric Weld Pak 140 welder. The thickest piece of mild steel that your Lincoln Easy MIG 140 can weld is 5/16 of an inch.

Key Specifications

| Power Source | 120V DC |

| Voltage | 110V |

| Duty Cycle | 22% @90amp |

| Weld | Aluminum with spool gun |

Key Features

Diamond Core Technology

The Diamond Core Technology is a proprietary technology developed by Lincoln Electric that optimizes the performance of the welding machine, making it a reliable and efficient choice for any welding project. The Lincoln Electric Weld Pak 140 features Diamond Core Technology, a unique feature that sets it apart from other welding machines. This technology provides a more stable arc and reduces spatter, which results in a cleaner and more consistent weld.

Additionally, the Diamond Core Technology increases the machine’s efficiency and allows for better control of the weld puddle, making it easier to achieve a higher-quality weld. This technology also provides a more stable and consistent wire feed, which can help to improve the overall welding performance and reduce the need for frequent adjustments.

Flux-cored Wire

The Lincoln Electric Weld Pak 140 is designed to handle flux-cored wire, a type of welding wire that is filled with flux and does not require an external gas shield. This makes it a great option for outdoor welding or welding in windy conditions. The flux-cored wire also provides a higher deposition rate, which means that it can weld faster than other types of welding wire, increasing productivity.

Moreover, the flux-cored wire is designed to reduce spatter, resulting in a cleaner and more consistent weld. The machine’s dual-groove quick-change drive roll allows easy changeover between solid and flux-cored wires. This feature makes the Lincoln Electric Weld Pak 140 ideal for welding projects requiring flux-cored wire.

22% @90Amp Duty Cycle

The duty cycle is typically expressed as a percentage, indicating the amount of time the machine can be used before it needs to be shut off to cool down. A higher duty cycle means the machine can be used for a longer period before cooling down.

The Lincoln Electric Weld Pak 140 has a duty cycle of 20% at 90A, which means that it can be used for 2 minutes out of every 10 minutes before needing to cool down. This feature makes the machine suitable for light-duty welding projects and allows the user to work efficiently without interruptions caused by cooling down periods.

Portable

Lincoln Electric Weld Pak 140 is not particularly lightweight. Still, it is not bulky, either, thanks to the transformer-based technology that it employs to provide high-quality results when welding steel. Nonetheless, at 50 pounds, this is one of the lightest small-scale welders, especially compared to the 57-pound Hobart Handler 190. Miller’s Millermatic 140 weighed 60 pounds, whereas the Forney 140 MIG weighed 62.

There is a built-in handle for convenient transport. In any case, I recommend that, as your first job with a new welder, you either purchase or construct a welding cart to hold an extra gas cylinder and any necessary supplies.

Pros

- Wide range of amperage settings

- Built-in wire feeder

- Dual-groove quick-change drive roll

- Built-in gas solenoid valve

- Thermal overload protection

- Compact and portable design

- Five-tap voltage control

Cons

- Not suitable for heavy-duty industrial use

- Low-duty cycle at maximum amperage

- Not precise wire feed speed adjustment

Final Verdict

Overall, the Lincoln Electric Weld Pak 140 is a great option for those looking for a dependable and high-performing welding machine that can handle a wide range of welding tasks. Still, it’s not the best option for heavy-duty industrial use, TIG welding, or welding aluminum. It’s important to carefully evaluate your welding needs and compare them with the machine’s capabilities before making a purchase decision.